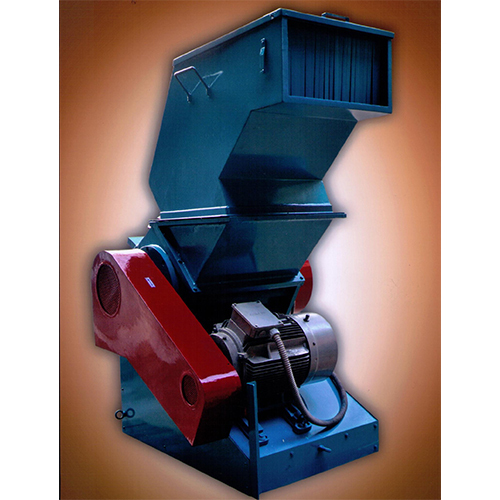

Plastic Granulator

Price 100000 INR/ Piece

Plastic Granulator Specification

- Type

- Plastic Granulator

- Material

- Mild Steel

- Capacity

- 150 - 500 kg/hr

- Computerized

- No

- Automatic Grade

- Automatic

- Control System

- PLC Control

- Drive Type

- Electric

- Screw Diameter

- 140 mm

- Power

- 25 HP

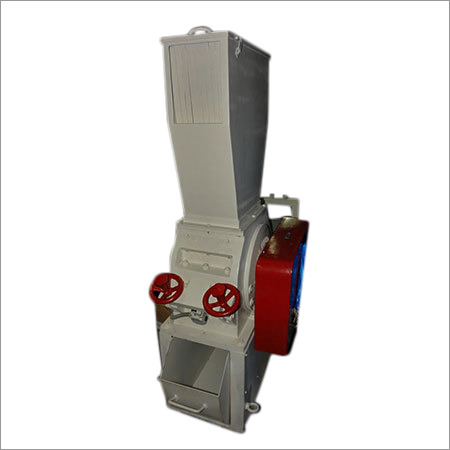

- Weight (kg)

- 1350 kg

- Dimension (L*W*H)

- 1600 x 1200 x 1800 mm

- Color

- Grey & Blue

- Application

- Plastic Waste Recycling, PET Bottle Crushing

- Noise Level

- less than 85 dB(A)

- Cooling System

- Air Cooled

- Voltage

- 415 V / 50 Hz

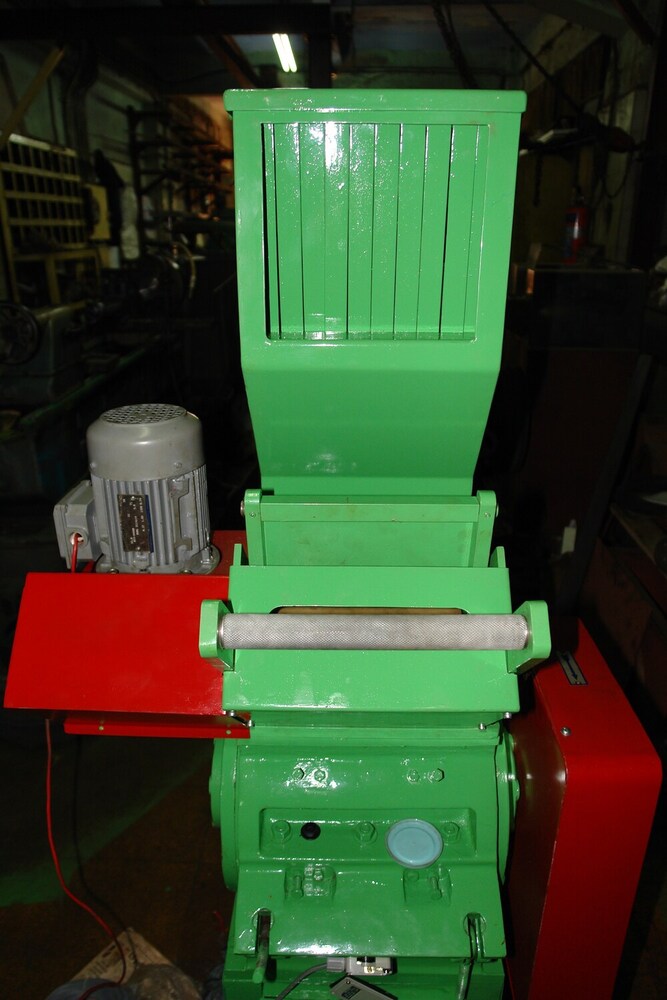

- Number of Rotating Blades

- 5

- Safety Features

- Overload Protector, Safety Switch

- Mobility

- Stationary (Castor Wheels Optional)

- Blade Material

- High Carbon Steel

- Feeding Hopper Type

- Automatic Large Feed Hopper

- Number of Fixed Blades

- 2

- Output Particle Size

- 6 - 12 mm (adjustable)

Plastic Granulator Trade Information

- Minimum Order Quantity

- 1 Piece

- FOB Port

- vadodara

- Payment Terms

- Cash Advance (CA), Cash in Advance (CID), Cheque

- Supply Ability

- 50 Pieces Per Month

- Delivery Time

- 2 Week

- Main Export Market(s)

- Australia, Asia, Africa

- Main Domestic Market

- All India

About Plastic Granulator

Plastic Granulator

We have become a developer entity in the business as a maker and provider of Plastic Granulator. This is manmade at our technically advanced production unit under the guidance of our experts by using best quality materials. Our granulator is widely used by our clients for making granules from the plastic scraps. This granulator is tested on the standard quality parameters before delivery. Plastic Granulatorare obtainable for our extensive client base at an reasonable price.

Key Features:

- High efficiency

- Quality material

- Easy to install

- Longer operational life

- Affordable price

Efficient Granulation for Plastic Recycling

The granulator is engineered for high-volume plastic waste recycling and PET bottle crushing. Equipped with a large automatic feed hopper and five high-carbon steel blades, it delivers consistent and adjustable particle sizes, enhancing plastic processing efficiency. Its robust construction ensures longevity and stable operation even in demanding industrial environments.

Advanced Safety and User-Friendly Operation

Operator safety is a priority, featuring an overload protector and safety switch. Its PLC control system streamlines use while reducing the risk of operational errors. Noise output remains below 85 dB(A), making it suitable for workplace environments where noise control is essential.

FAQs of Plastic Granulator:

Q: How does the automatic large feed hopper improve plastic waste processing?

A: The automatic large feed hopper allows for continuous and efficient feeding of plastic waste and PET bottles, minimizing downtime and reducing manual handling, which increases overall productivity during recycling operations.Q: What is the benefit of having high carbon steel blades in this granulator?

A: High carbon steel blades offer excellent sharpness, durability, and wear resistance, ensuring precise and effective granulation over extended periods and reducing the frequency of blade replacement.Q: When is it necessary to adjust the output particle size, and how is this achieved?

A: Adjusting the output particle size is beneficial when different recycling processes or end products require specific granule sizes. This granulator allows you to set the output between 6 mm and 12 mm easily, providing flexibility based on the recycling requirements.Q: Where should this granulator be installed for optimal performance?

A: Ideally, the granulator should be placed in a well-ventilated area with sturdy flooring to support its 1350 kg weight. Although stationary, optional castor wheels can be fitted for mobility if relocation within the facility is required.Q: What safety features does the granulator include?

A: This granulator is equipped with an overload protector and a safety switch, helping to prevent machine damage due to excessive loads and ensuring operator safety by shutting down the machine in hazardous situations.Q: How does the air cooling system enhance the granulation process?

A: The air-cooled system prevents overheating of the machine during continuous operation, ensuring efficient blade performance, prolonged machine life, and safer working conditions.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Plastic Processing Machinery Category

Automatic Lumps Granulator

Price 100000 INR / Piece

Minimum Order Quantity : 1 Piece

Drive Type : Other, Electric Motor

Material : Mild Steel

Automatic Grade : Automatic

Computerized : No

Plastic Film Grinder

Price 85000 INR / Piece

Minimum Order Quantity : 1 Piece

Drive Type : Other, Electric Motor

Material : Mild Steel Body with Alloy Steel Blades

Automatic Grade : SemiAutomatic

Computerized : No

Plastic Film Dryer Machine

Minimum Order Quantity : 1 Plant

Drive Type : Other, Electric

Material : Stainless Steel

Automatic Grade : Automatic

Computerized : Yes

Plastic Granulator Machine

Price 350000 INR / Unit

Minimum Order Quantity : 1 Unit

Drive Type : Direct

Material : MS

Automatic Grade : SemiAutomatic

Computerized : No

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry