Plastic Film Dryer Machine

Plastic Film Dryer Machine Specification

- Type

- Plastic Film Dryer Machine

- Material

- Stainless Steel

- Capacity

- 300-500 kg/hr

- Computerized

- Yes

- Automatic Grade

- Automatic

- Control System

- PLC Control

- Drive Type

- Electric

- Screw Diameter

- 120 mm

- Power

- 65 kW

- Weight (kg)

- 1500

- Dimension (L*W*H)

- 3200 x 1800 x 2300 mm

- Color

- Blue & Silver

- Surface Treatment

- Polished/Anti-rust Coated

- Noise Level

- Less than 80 dB

- Operating Temperature Range

- Room temperature to 120°C

- Frequency

- 50/60 Hz

- Voltage

- 380V / 50Hz

- Heating Method

- Electric Heater & Blower

- Application

- Used for drying washed plastic films such as LDPE, HDPE, and PP

- Safety Features

- Overload & Overheat Protection

- Moisture Content After Drying

- Less than 5%

- Feeding Method

- Automatic Conveyor

Plastic Film Dryer Machine Trade Information

- Minimum Order Quantity

- 1 Plant

- Supply Ability

- 2 Plants Per Month

- Delivery Time

- 15-30 Days

- Main Domestic Market

- All India

About Plastic Film Dryer Machine

Superior Drying Efficiency

Engineered for reliable drying, this machine delivers outstanding moisture reduction for LDPE, HDPE, and PP plastic films. The combination of electric heating and forced air circulation ensures even, rapid drying, producing films with moisture content of less than 5%. This feature not only promotes better quality recycling but also helps prevent issues such as clumping or contamination in downstream processing.

Automated and User-Friendly Operation

This dryer integrates a fully automated process, facilitated by a PLC control system and automatic conveyor feeding. Operators can easily manage and monitor the drying parameters, including temperature settings up to 120C. The computerized system ensures precise control, higher productivity, and consistent output, while the safety features provide operational peace of mind.

Robust Construction and Easy Installation

Manufactured from durable stainless steel and treated for corrosion resistance, the machine is built to last and withstand rigorous industrial use. Its design allows for simple installation and integration within existing plastic recycling systems. The blue and silver exterior combines functionality with a modern aesthetic, reflecting its industrial-grade performance.

FAQ's of Plastic Film Dryer Machine:

Q: How does the Plastic Film Dryer Machine operate automatically?

A: The machine uses an automatic conveyor feeding mechanism and PLC-controlled system, which streamlines the entire drying process. Simply load the washed plastic films, and the system manages drying parameters, ensuring consistent results with minimal manual intervention.Q: What types of plastic films can be dried using this machine?

A: This dryer is engineered specifically for LDPE, HDPE, and PP plastic films. Its adjustable operating temperature and customizable settings make it versatile for a variety of post-washing film types encountered in recycling plants.Q: When should the Plastic Film Dryer Machine be used in the recycling process?

A: It is ideal to use this dryer immediately after the washing and rinsing phase for plastic films. Removing excess moisture before further processing or pelletizing improves operational efficiency and product quality.Q: Where is the machine best suited for installation?

A: The machine is designed for industrial applications and is most suitable for installation in recycling plants, material recovery facilities, or plastic processing units, where continuous, high-volume drying of plastic films is required.Q: What is the drying process and how is low moisture achieved?

A: The process involves feeding washed films into the dryer via a conveyor, where an electric heater and blower circulate hot air uniformly. This effectively reduces the moisture content to below 5%, optimizing films for subsequent recycling steps.Q: What benefits does the Plastic Film Dryer Machine offer?

A: Benefits include reduced drying times, improved material quality, safer operations due to advanced protection features, and consistent performance enabled by computerized controls. Its robust construction ensures longevity and minimal maintenance.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Plastic Processing Machinery Category

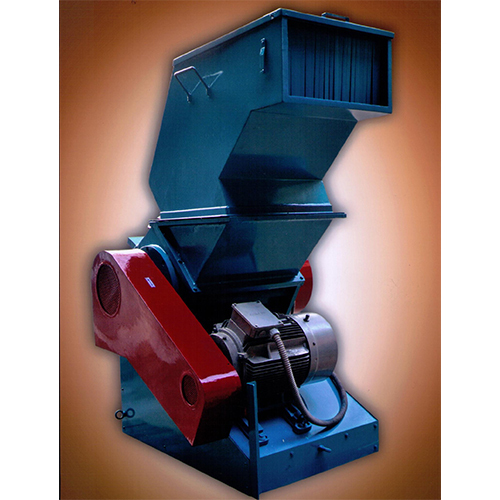

Automatic Lumps Granulator

Price 100000 INR / Piece

Minimum Order Quantity : 1 Piece

Type : Automatic Lumps Granulator

Capacity : Up to 500 kg/hr Kg/hr

Computerized : No

Drive Type : Other, Electric Motor

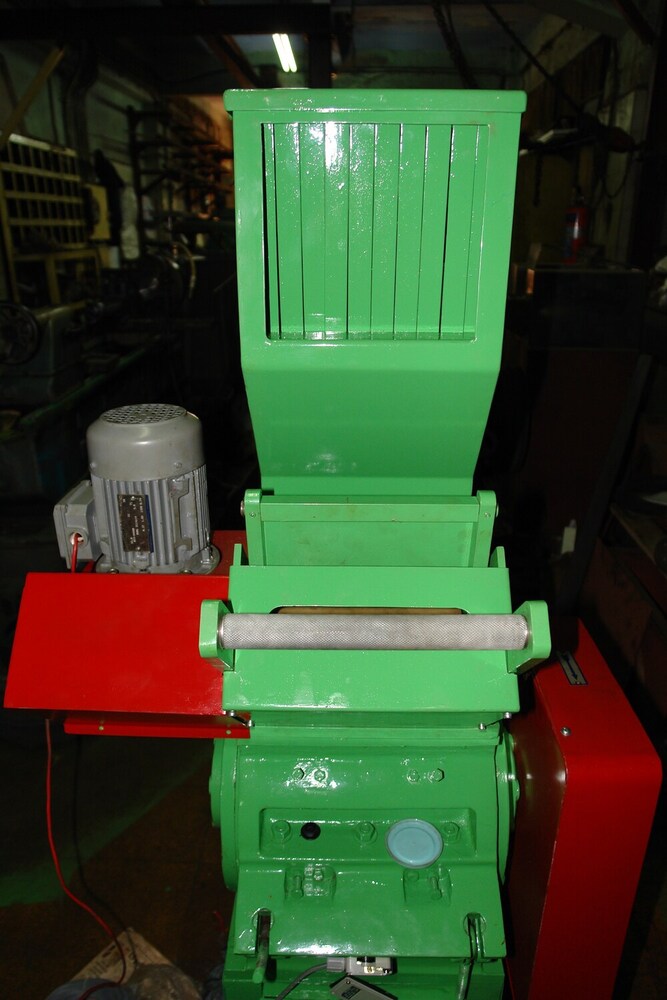

Lumps Granulators

Price 100000 INR / Piece

Minimum Order Quantity : 1 Piece

Type : Lumps Granulator

Capacity : 80350 kg/hr

Computerized : No

Drive Type : Other, Electric Motor

Industrial Plastic Grinder

Price 100000 INR / Piece

Minimum Order Quantity : 1 Piece

Type : Industrial Plastic Grinder

Capacity : 100300 kg/hr Kg/hr

Computerized : No

Drive Type : Other, Electric

Plastic Film Grinder

Price 85000 INR / Piece

Minimum Order Quantity : 1 Piece

Type : Plastic Film Grinder

Capacity : 150400 kg/hr Kg/hr

Computerized : No

Drive Type : Other, Electric Motor

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry