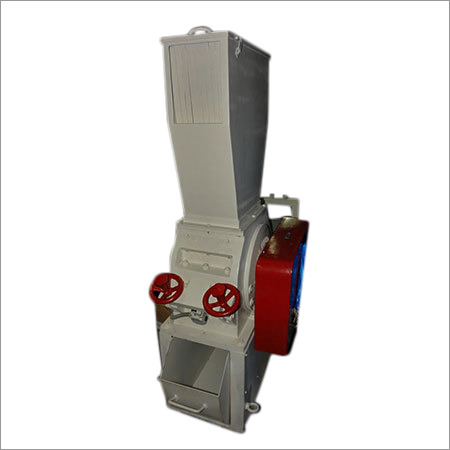

Plastic Film Grinder

Price 85000 INR/ Piece

Plastic Film Grinder Specification

- Type

- Plastic Film Grinder

- Material

- Mild Steel Body with Alloy Steel Blades

- Capacity

- 150-400 kg/hr Kg/hr

- Computerized

- No

- Automatic Grade

- Semi-Automatic

- Drive Type

- Electric Motor

- Power

- 15 HP Horsepower (HP)

- Weight (kg)

- 360 kg Kilograms (kg)

- Dimension (L*W*H)

- 114 x 90 x 151 cm Millimeter (mm)

- Color

- Blue & Silver

- Application

- Grinding of Plastic Films, Bags, Sheets

- Blade Material

- High Carbon Alloy Steel

- Motor Speed

- 1440 RPM

- Safety Features

- Emergency Stop Switch, Overload Protection

- Noise Level

- 85 dB

- Feed Opening Size

- 400 x 260 mm

- Voltage

- 415V / 3 Phase

- Cooling System

- Air Cooled

- Output Size

- 6-12 mm (Adjustable)

Plastic Film Grinder Trade Information

- Minimum Order Quantity

- 1 Piece

- FOB Port

- VADODARA

- Payment Terms

- Cash Advance (CA), Cash in Advance (CID), Cheque

- Supply Ability

- 5 Pieces Per Month

- Delivery Time

- 15 Days

- Sample Policy

- Contact us for information regarding our sample policy

- Main Export Market(s)

- Asia, Middle East, Africa

- Main Domestic Market

- All India

About Plastic Film Grinder

Powerful Grinding and Adjustable Outputs

The grinder features a high-performance 15 HP electric motor paired with precision alloy steel blades, enabling consistent output particles between 6 and 12 mm. The system is optimized for plastics, handling films, bags, and sheets with ease and transforming them into uniform, manageable pieces for recycling or disposal.

Safety and Efficiency

Operational safety is prioritized through an emergency stop switch and overload protection mechanism. The intelligent air-cooled system keeps the machine running cool and stable, while the noise level remains at or below 85 dB, supporting a safer, more comfortable workspace for operators.

User-Friendly Operation and Built to Last

This semi-automatic grinder uses a straightforward button/panel control system, making it accessible even for less experienced operators. The robust mild steel body combined with high carbon alloy blades ensures longevity, while the blue and silver finish presents a modern, professional appearance.

FAQs of Plastic Film Grinder:

Q: How do I operate the Plastic Film Grinder?

A: To operate the grinder, feed plastic films, bags, or sheets into the 400 x 260 mm opening, then use the button/panel control to turn on and monitor the process. Adjust the output size from 6 to 12 mm as needed. Always ensure all safety features, like the emergency stop, are functional before use.Q: What types of plastics can this grinder process?

A: This machine is specifically designed to grind plastic films, bags, and sheets. Its robust build and high carbon alloy steel blades allow it to handle various soft plastics effectively, making it ideal for recycling and waste management tasks involving flexible plastic materials.Q: When should I use the emergency stop feature?

A: The emergency stop switch should be used immediately if you encounter any unsafe operating conditions, machine malfunctions, or potential hazards during grinding. This feature rapidly halts the machine to protect both the operator and the equipment.Q: Where is this plastic film grinder typically used?

A: This grinder is commonly used in recycling facilities, plastic manufacturing plants, and waste management units across India and globally. As an exporter and supplier, we provide solutions for clients requiring efficient plastic size reduction and recycling machinery.Q: What is the process for adjusting the output size?

A: You can modify the output particle size between 6 and 12 mm by adjusting the blade settings through the control panel. Please consult the user manual for specific instructions, ensuring adjustment is made while the machine is turned off and secured.Q: What are the main benefits of using this grinder?

A: Key benefits include high throughput (150-400 kg/hr), precision grinding with adjustable size, reduced noise ( 85 dB), safety features, and durable construction. These features collectively help streamline plastic waste processing and enhance workplace safety and operational efficiency.Q: Is this grinder fully automatic or does it require manual intervention?

A: This is a semi-automatic machine. While the primary grinding process is automated, operators will need to load materials, adjust settings, and oversee machine operation using the button/panel interface.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Plastic Processing Machinery Category

Lumps Granulators

Price 100000 INR / Piece

Minimum Order Quantity : 1 Piece

Type : Lumps Granulator

Weight (kg) : 900 kg

Capacity : 80350 kg/hr

Drive Type : Other, Electric Motor

Plastic Granulator

Price 100000 INR / Piece

Minimum Order Quantity : 1 Piece

Type : Plastic Granulator

Weight (kg) : 1350 kg

Capacity : 150 500 kg/hr

Drive Type : Other, Electric

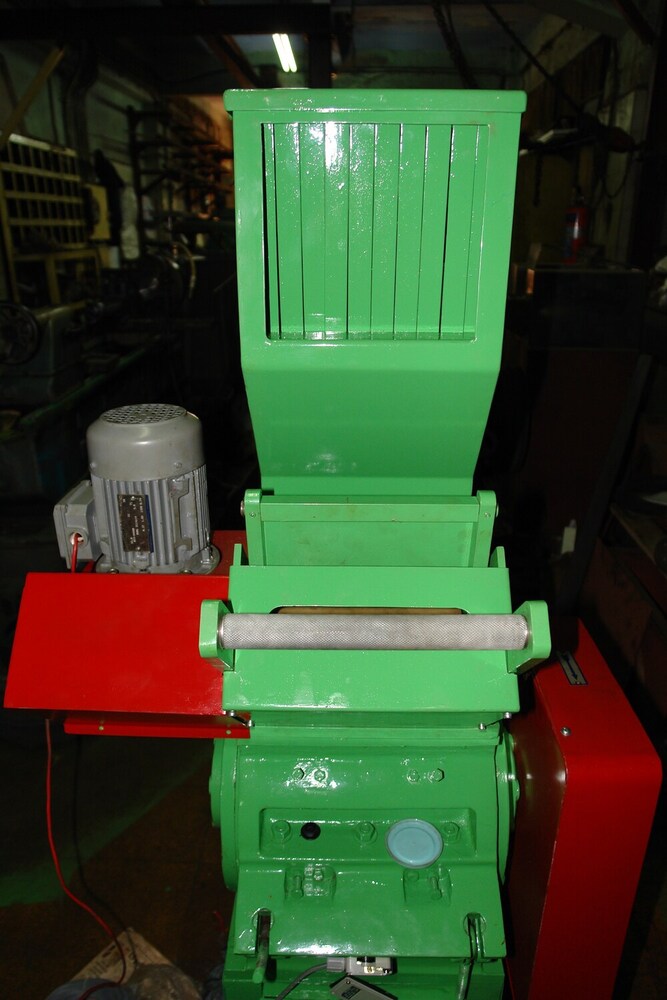

Industrial Plastic Grinder

Price 100000 INR / Piece

Minimum Order Quantity : 1 Piece

Type : Industrial Plastic Grinder

Weight (kg) : 420 kg Kilograms (kg)

Capacity : 100300 kg/hr Kg/hr

Drive Type : Other, Electric

Plastic Granulator Machine

Price 350000 INR / Unit

Minimum Order Quantity : 1 Unit

Type : Plastic Granulator Machine

Weight (kg) : 1000 approx Kilograms (kg)

Capacity : 500 Kg/hr

Drive Type : Direct

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry