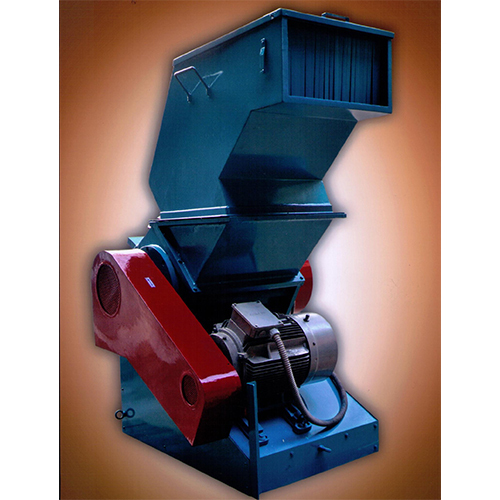

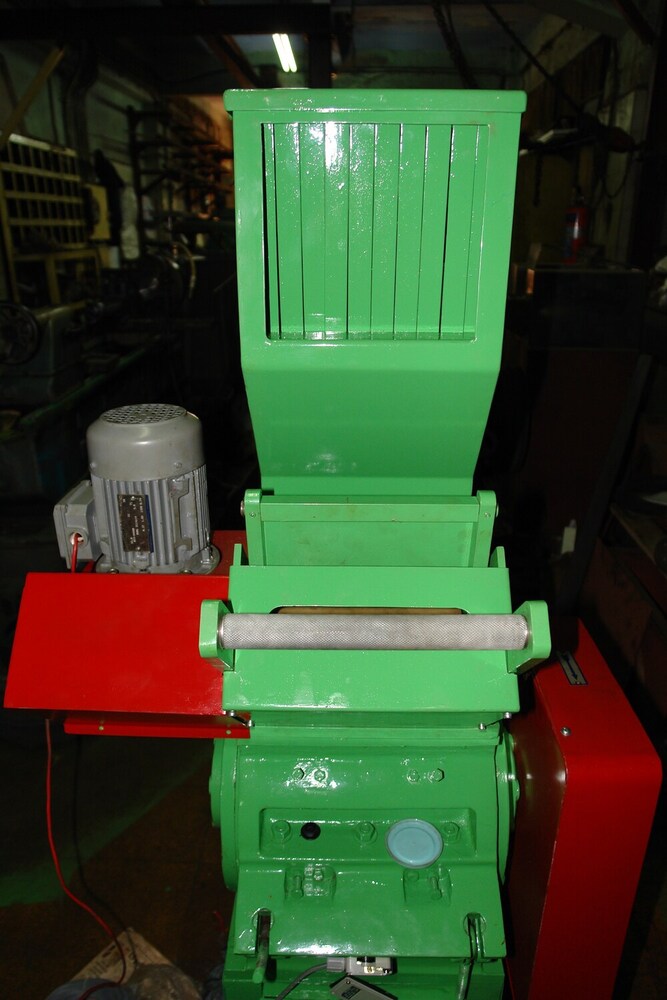

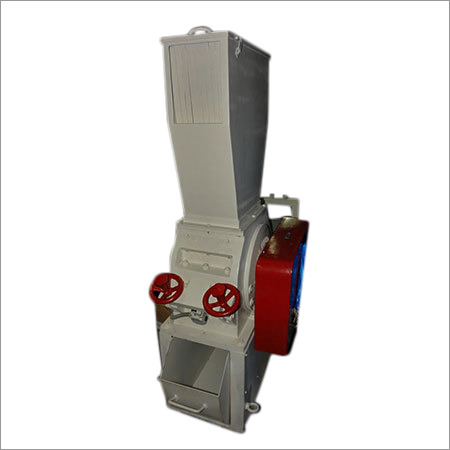

Plastic Granulator Machine

Price 350000 INR/ Unit

Plastic Granulator Machine Specification

- Type

- Plastic Granulator Machine

- Material

- MS

- Capacity

- 500 Kg/hr

- Computerized

- No

- Automatic Grade

- Semi-Automatic

- Control System

- Human Machine Interface

- Drive Type

- Direct

- Weight (kg)

- 1000 approx Kilograms (kg)

- Color

- White

Plastic Granulator Machine Trade Information

- Minimum Order Quantity

- 1 Unit

- FOB Port

- Mundra

- Payment Terms

- Cash in Advance (CID), Cash Advance (CA)

- Supply Ability

- 10 Units Per Month

- Delivery Time

- 2 Months

- Main Export Market(s)

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

- Main Domestic Market

- All India

About Plastic Granulator Machine

Plastic Granulator

PM Granulators are known for their high over all quality. Manufactured scientifically to achieve high efficiency of cutting, Ruggedness , long service life and trouble free operations. With a wide range of Granulators we have the perfect solutions for your size reduction requirements. PM has a long manufacturing experience in Granulators which dates back since 1972.

Key Features:

- High Power efficiency

- Precisely designed

- Superior performance

- Negligible maintenance

- Avail in various specifications

Efficient Plastic Recycling at Scale

With a capacity of 500 kg/hr, this Plastic Granulator Machine delivers reliable granulation for various plastic types. Its semi-automatic design combines user-friendly operation through the HMI control system and the resilience of MS construction. Ideal for manufacturers and recyclers looking to enhance their operational efficiency while supporting environmental sustainability.

Durable Design for Industrial Use

Engineered in mild steel and coated with a sleek white finish, this granulator withstands rigorous daily use. The direct drive ensures effective power transmission and reduced maintenance, providing a long lifespan even in demanding conditions. Its approximately 1000 kg build is optimized for stability and robust performance.

FAQ's of Plastic Granulator Machine:

Q: How is the plastic granulation process carried out using this machine?

A: The process involves feeding plastic waste into the machine, which then uses rotating and stationary blades to cut and shred the material into uniform granules. The Human Machine Interface makes it easy to control the process and monitor production output.Q: What are the primary benefits of using this Plastic Granulator Machine?

A: Key benefits include high processing efficiency (500 kg/hr), robust construction from MS for longevity, a semi-automatic setup that minimizes operator workload, and an HMI-powered control panel that enhances operational ease.Q: When should I use a semi-automatic granulator instead of a fully automatic or manual model?

A: A semi-automatic granulator is ideal when you require a balance of productivity and user control. It suits facilities handling medium to large volumes that don't require full automation or want to maintain hands-on oversight during operation.Q: Where is the ideal installation site for this granulator machine?

A: The machine should be installed in an industrial setting with adequate floor strength to support its approximate 1000 kg weight and sufficient ventilation for heat dissipation during high-capacity operations.Q: What materials can this granulator handle?

A: It is optimized for a variety of plastic waste, including industrial scrap, post-consumer plastics, and production off-cuts, ensuring versatile usage across different sectors.Q: How does the direct drive system improve machine performance?

A: The direct drive mechanism delivers efficient power transfer with less energy loss and wear, which reduces maintenance requirements and prolongs operational life of the granulator.Q: What makes this machine suitable for exporters and manufacturers in India?

A: Its sturdy MS build, high throughput, and user-friendly HMI controls cater well to Indian industrial demands. The semi-automatic design and reliable supplier network from India make it a practical choice for both domestic and overseas clients.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Plastic Processing Machinery Category

Automatic Lumps Granulator

Price 100000 INR / Piece

Minimum Order Quantity : 1 Piece

Computerized : No

Capacity : Up to 500 kg/hr Kg/hr

Drive Type : Other, Electric Motor

Dimension (L*W*H) : 2200 x 900 x 1400 mm Millimeter (mm)

Plastic Granulator

Price 100000 INR / Piece

Minimum Order Quantity : 1 Piece

Computerized : No

Capacity : 150 500 kg/hr

Drive Type : Other, Electric

Dimension (L*W*H) : 1600 x 1200 x 1800 mm

Industrial Plastic Grinder

Price 100000 INR / Piece

Minimum Order Quantity : 1 Piece

Computerized : No

Capacity : 100300 kg/hr Kg/hr

Drive Type : Other, Electric

Dimension (L*W*H) : 1150 x 950 x 1350 mm Millimeter (mm)

Plastic Film Grinder

Price 85000 INR / Piece

Minimum Order Quantity : 1 Piece

Computerized : No

Capacity : 150400 kg/hr Kg/hr

Drive Type : Other, Electric Motor

Dimension (L*W*H) : 114 x 90 x 151 cm Millimeter (mm)

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry