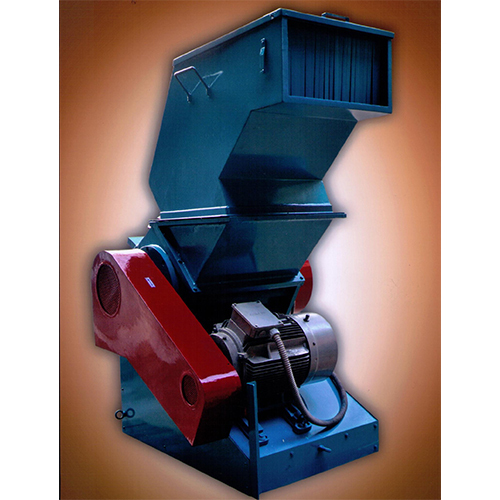

Lumps Granulators

Price 100000 INR/ Piece

Lumps Granulators Specification

- Bend Radius

- Standard

- Type

- Lumps Granulator

- Material

- Mild Steel / Stainless Steel

- Capacity

- 80-350 kg/hr

- Computerized

- No

- Automatic Grade

- Automatic

- Control System

- PLC Based Control

- Drive Type

- Electric Motor

- Screw Diameter

- Customizable as per Model

- Power

- 10-30 HP

- Weight (kg)

- 900 kg

- Dimension (L*W*H)

- 1700 mm x 1250 mm x 1420 mm

- Color

- Blue & Silver

- Frequency

- 50-60 Hz

- Lubrication Type

- Automatic

- Feeding Hopper Size

- Large Hopper for Bulk Input

- Cutter Type

- Rotating & Stationary Blades

- Output Particle Size

- 10-20 mm (Adjustable)

- Application

- Plastic Lumps, Sheet, Profile Recycling

- Safety Features

- Overload Protection, Emergency Stop Switch

- Blade Material

- Alloy Steel

- Noise Level

- Below 85 dB(A)

- Voltage

- 415V AC, 3 Phase

- Cooling System

- Air Cooled

Lumps Granulators Trade Information

- Minimum Order Quantity

- 1 Piece

- FOB Port

- vadodara

- Payment Terms

- Cash Advance (CA), Cash in Advance (CID), Cheque

- Supply Ability

- 1 Piece Per Month

- Delivery Time

- 15 Days

- Main Domestic Market

- All India

About Lumps Granulators

Lumps Granulators

We have become a developer entity in the business as a producer and supplier of Plastic Granulator. It is produced at our technically progressive production unit under the direction of our specialists by using best excellence materials. It is extensively used by our customers to produce granules from the plastic scrapings. This is tested on the usual quality constraints prior to delivery. Plastic Granulator is accessible for our extensive customer base at an reasonable price.

Key Features:

- Reliability

- Durability

- Easy to install

- Longer operational life

- High efficiency

High-Efficiency Bulk Plastic Recycling

This advanced granulator is engineered to handle bulk input, making it ideal for large-scale recycling operations. Its large hopper accommodates sizeable lumps, sheets, and profiles for uninterrupted processing, streamlining the preparation phase for plastic reuse industries. The rugged construction ensures dependability and longevity during intensive workloads.

Automated & Safe Operation

With its PLC-based automatic controls, the Lumps Granulator offers user-friendly operation and precise output adjustments. Safety remains paramount, thanks to integrated overload protection and an accessible emergency stop switch. These features safeguard operators while maintaining productivity, even during prolonged use.

Fine-Tuned Output Quality

The rotating and stationary alloy steel blades deliver uniform granulation with easily adjustable particle sizes from 10 to 20 mm. Combined with continuous air cooling and automatic lubrication, the granulator ensures long blade life and consistent granule quality, supporting various downstream recycling processes.

FAQs of Lumps Granulators:

Q: How does the large hopper benefit bulk plastic recycling?

A: The large feeding hopper is specifically designed to handle bulk quantities of plastic lumps, sheets, and profiles, allowing for continuous input and reducing the need for frequent manual loading. This improves operational efficiency and throughput, making it suitable for high-volume recycling environments.Q: What safety features are incorporated in this lumps granulator?

A: Safety has been prioritized through the inclusion of overload protectionpreventing damage from excessive loadsand an emergency stop switch that allows immediate shutdown during unexpected situations, ensuring the operators safety at all times.Q: When should the particle size output be adjusted, and how?

A: Adjustments to the output particle size (1020 mm) should be made depending on downstream processing requirements. Using the PLC control system, operators can set the desired size, ensuring the granulate matches the intended recycling or manufacturing process.Q: Where can this granulator be effectively used?

A: The Lumps Granulator is highly effective in plastic recycling facilities, manufacturing plants, and processing centers that handle leftover plastic lumps, sheets, and profiles. Its robust design makes it well-suited for industrial settings demanding high reliability.Q: What types of materials can the machine process?

A: This granulator processes rigid plastic lumps, sheets, and profiles, thanks to tough alloy steel blades and a powerful electric motor. It efficiently reduces oversized plastic waste into uniform, manageable granules suitable for further processing.Q: How does the automatic lubrication and air-cooled system improve machine lifespan?

A: Automatic lubrication ensures the moving parts remain well-oiled, reducing friction and wear, while the air-cooled system maintains optimal operating temperatures. Both features minimize maintenance needs and extend the granulators service life.Q: What benefits do users enjoy with the PLC-based control system?

A: The PLC-based control system provides intuitive operation, precise control over settings such as granule size, and reliable automation. This leads to repeatable results, improved consistency, and user confidence during daily operation.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Plastic Processing Machinery Category

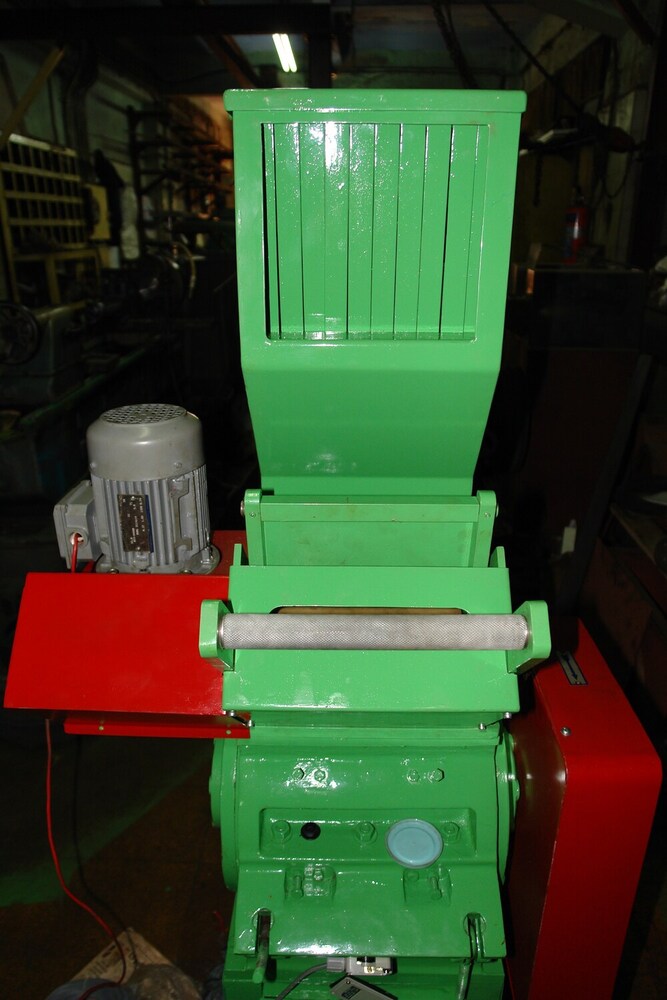

Automatic Lumps Granulator

Price 100000 INR / Piece

Minimum Order Quantity : 1 Piece

Dimension (L*W*H) : 2200 x 900 x 1400 mm Millimeter (mm)

Material : Mild Steel

Capacity : Up to 500 kg/hr Kg/hr

Type : Automatic Lumps Granulator

Plastic Granulator

Price 100000 INR / Piece

Minimum Order Quantity : 1 Piece

Dimension (L*W*H) : 1600 x 1200 x 1800 mm

Material : Mild Steel

Capacity : 150 500 kg/hr

Type : Plastic Granulator

Industrial Plastic Grinder

Price 100000 INR / Piece

Minimum Order Quantity : 1 Piece

Dimension (L*W*H) : 1150 x 950 x 1350 mm Millimeter (mm)

Material : Mild Steel

Capacity : 100300 kg/hr Kg/hr

Type : Industrial Plastic Grinder

Plastic Film Grinder

Price 85000 INR / Piece

Minimum Order Quantity : 1 Piece

Dimension (L*W*H) : 114 x 90 x 151 cm Millimeter (mm)

Material : Mild Steel Body with Alloy Steel Blades

Capacity : 150400 kg/hr Kg/hr

Type : Plastic Film Grinder

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry