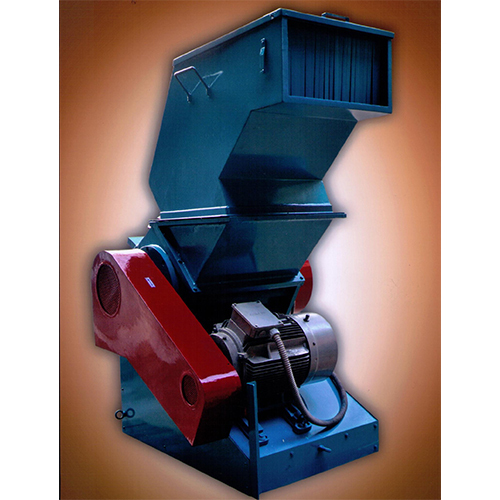

Automatic Lumps Granulator

Price 100000 INR/ Piece

Automatic Lumps Granulator Specification

- Type

- Automatic Lumps Granulator

- Material

- Mild Steel

- Capacity

- Up to 500 kg/hr Kg/hr

- Computerized

- No

- Automatic Grade

- Automatic

- Control System

- PLC Control

- Drive Type

- Electric Motor

- Screw Diameter

- 120 mm Millimeter (mm)

- Power

- 7.5 kW Watt (w)

- Weight (kg)

- 1200 kg Kilograms (kg)

- Dimension (L*W*H)

- 2200 x 900 x 1400 mm Millimeter (mm)

- Color

- Silver & Blue

- Feeding Method

- Automatic Hopper Loader

- Application

- Plastic lumps, Scrap, Regrind processing

- Voltage

- 415V, 3 Phase

- Mobility

- Caster Wheels

- No. of Blades

- 5 Rotating + 2 Fixed

- Finish

- Powder Coated

- Blade Material

- Alloy Steel

- Noise Level

- <80 dB

- Cutting Chamber Size

- 400 x 350 mm

- Safety Features

- Emergency Stop, Overload Protection

Automatic Lumps Granulator Trade Information

- Minimum Order Quantity

- 1 Piece

- FOB Port

- VADODARA

- Payment Terms

- Cash Advance (CA), Cash in Advance (CID), Cheque

- Supply Ability

- 5 Pieces Per Month

- Delivery Time

- 15 Days

- Sample Policy

- Contact us for information regarding our sample policy

- Main Export Market(s)

- Middle East, Asia, Africa

- Main Domestic Market

- All India

About Automatic Lumps Granulator

You will get premium quality automatic lumps granulator here at Plastic Machinery. It is most commonly found in plastic industries and workshops. It is designed for grinding scrap parts as well as reducing waste/rejected products. This machine is accustomed with rotary grinders which provides faster and efficient performance. In addition to this, the said product runs on low power and requires less maintenance. Automatic lumps granulator possesses robust structure, seamless finishing and abrasion resistance. It breaks down plastic products efficiently into small pieces. Customers can get these in different specifications.

High-Performance Granulation

Engineered for rigorous industrial applications, the granulator processes plastic lumps, scrap, and regrind at rates of up to 500 kg per hour. Its automatic hopper loader streamlines feeding, ensuring efficient and uninterrupted operation for jobs of any scale. The robust alloy steel blades guarantee precise cutting and long-lasting sharpness.

Safety and User Comfort

Featuring emergency stop and overload protection systems, this granulator prioritizes operator safety. The noise level remains below 80 dB, creating a more pleasant working environment. Mounted on caster wheels, it is easily movable between workstations as needed for flexible production setups.

Advanced Control and Durability

Equipped with a PLC-based control system, operators can quickly adjust settings for optimal performance. The granulator is built from powder-coated mild steel for resilience, while the durable electric drive and corrosion-resistant finish ensure reliability under demanding conditions.

FAQs of Automatic Lumps Granulator:

Q: How does the automatic hopper loader enhance operation efficiency?

A: The automatic hopper loader streamlines the feeding process, allowing continuous input of plastic lumps or regrind materials without manual intervention. This not only increases productivity but also ensures consistent feed rates for optimal granulation results.Q: What safety features are included with the granulator?

A: This machine is equipped with vital safety features, including an emergency stop button for immediate shutdown, as well as overload protection to safeguard both operator and equipment during heavy-duty operation.Q: When should the granulator be used in plastic processing plants?

A: It is ideal for use after molding or extrusion processes, where plastic lumps, scrap, or rejected parts need to be reduced in size for recycling or further processing. The machines high capacity and efficiency make it suitable for continuous industrial operation.Q: Where is the Automatic Lumps Granulator typically installed?

A: Commonly found in industrial settings such as plastic manufacturing plants, recycling units, or processing facilities across India, the granulator operates efficiently wherever high-volume plastic waste reduction is needed.Q: What is the benefit of alloy steel blades in this granulator?

A: Alloy steel blades provide exceptional durability, sharpness, and cutting precision. This translates into longer blade life, reduced maintenance frequency, and efficient size reduction of tough plastic lumps and scraps.Q: How does the PLC control system enhance machine usability?

A: The integrated PLC control system enables users to monitor and adjust operational parameters with ease, improving operational accuracy, reducing manual errors, and ensuring consistent output quality.Q: What materials can this granulator process?

A: This granulator is engineered to handle a variety of plastic forms, including lumps, scrap, and regrind, making it versatile for processing materials from different production stages and maximizing recycling efficiency.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Plastic Processing Machinery Category

Lumps Granulators

Price 100000 INR / Piece

Minimum Order Quantity : 1 Piece

Material : Mild Steel / Stainless Steel

Weight (kg) : 900 kg

Computerized : No

Color : Blue & Silver

Industrial Plastic Grinder

Price 100000 INR / Piece

Minimum Order Quantity : 1 Piece

Material : Mild Steel

Weight (kg) : 420 kg Kilograms (kg)

Computerized : No

Color : Blue & Silver

Plastic Film Dryer Machine

Minimum Order Quantity : 1 Plant

Material : Stainless Steel

Weight (kg) : 1500

Computerized : Yes

Color : Blue & Silver

Plastic Scrap Grinders

Price 40000 INR / Piece

Minimum Order Quantity : 1 Piece

Material : Mild Steel

Weight (kg) : 380 kg

Computerized : No

Color : Green

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry