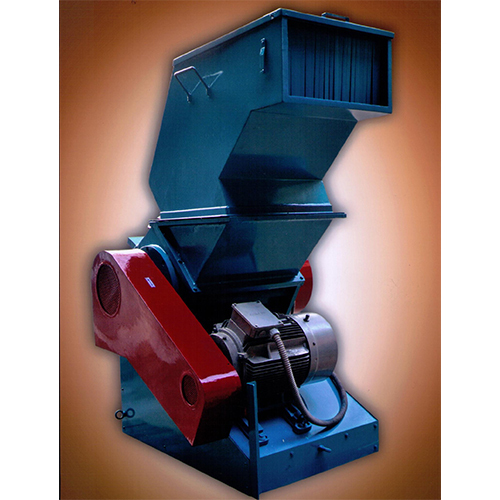

Plastic Grinding Machine

Price 40000 INR/ Piece

Plastic Grinding Machine Specification

- Type

- Plastic Grinding Machine

- Material

- Mild Steel

- Capacity

- 120-150 kg/hr Kg/hr

- Computerized

- No

- Drive Type

- Belt Drive

- Screw Diameter

- 110 mm Millimeter (mm)

- Weight (kg)

- 700 kg Kilograms (kg)

- Dimension (L*W*H)

- 48 x 36 x 60 inch Inch (in)

- Color

- Green

- Safety Features

- Overload Protection, Emergency Stop

- Motor Type

- Three Phase Induction Motor

- Feeding Size

- Up to 300 mm

- Blade Material

- High Carbon Steel

- No of Moving Blades

- 6

- No of Fixed Blades

- 4

- Finishing Type

- Paint Coated

- Voltage

- 415 V

- Application

- Plastic Scrap Grinding, Recycling

- Noise Level

- Less than 85 dB

- Frequency

- 50 Hz

Plastic Grinding Machine Trade Information

- Minimum Order Quantity

- 1 Piece

- FOB Port

- vadodara

- Supply Ability

- 50 Pieces Per Month

- Delivery Time

- 2 Week

- Main Export Market(s)

- Asia, Australia, South America, Middle East, Africa

- Main Domestic Market

- All India

About Plastic Grinding Machine

Plastic Grinding Machine

The support of our technocrats and progressive engineering unit aids us in making, exporting and supplying Plastic Grinding Machine. The presented machine is primarily taken into use to re-process the scrap substances. The accessible machine is planned and factory-made by employing quality-approved apparatuses and ultra-modern techniques in conformism with set manufacturing canons. The obtainable Plastic Grinding Machine is manufactured for patrons in numerous technical stipulations at market chief prices.

Key Features:

- Effective functionality

- Uniform and continuous production

- Energy efficient

- Longer service life

- Avail in several technical specifications

Precision Engineering for Plastic Recycling

Crafted for durability and performance, this plastic grinding machine integrates high carbon steel blades and a powerful induction motor for seamless scrap processing. The six moving and four fixed blades ensure a consistent granulate size. With feed capacity up to 300 mm and processing rates up to 150 kg/hr, it supports recycling operations with high efficiency.

Robust Safety Features and User-Friendly Controls

Designed with user safety in mind, the machine includes overload protection and an emergency stop button. Its semi-automatic operation with manual control system makes it easy to operate and maintain, catering to both small and medium-scale recycling facilities while delivering peace of mind for operators.

FAQs of Plastic Grinding Machine:

Q: How does the plastic grinding machine contribute to recycling processes?

A: This machine efficiently grinds plastic scrap materials into smaller granules, making them suitable for further processing or reuse in manufacturing, effectively supporting recycling and waste reduction.Q: What is the recommended feeding size for optimal performance?

A: For best results, feed plastic materials up to 300 mm in size. This ensures efficient grinding and consistent output while preventing blade overload and potential machine jamming.Q: Where can this plastic grinding machine be installed and used?

A: It is suitable for installation in plastic recycling plants, manufacturing units, and scrap processing facilities, especially those requiring capacities between 120-150 kg/hr.Q: When should the emergency stop feature be activated?

A: The emergency stop button should be pressed immediately in any hazardous situation, such as blade jams, electrical faults, or operator emergencies, ensuring user safety and preventing damage.Q: What safety measures are incorporated in this machine?

A: It includes overload protection to prevent motor damage and an emergency stop feature for immediate shutdown during irregularities, enhancing operational safety for users.Q: How does the machine handle noise during operation?

A: Engineered to operate below 85 dB, the machine minimizes noise exposure, ensuring a safer and more comfortable working environment for operators.Q: What are the main benefits of using this semi-automatic plastic grinding machine?

A: Key benefits include efficient plastic scrap processing, reliable safety features, robust construction for heavy-duty usage, and user-friendly manual control for easy operation and maintenance.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Plastic Processing Machinery Category

Automatic Lumps Granulator

Price 100000 INR / Piece

Minimum Order Quantity : 1 Piece

Drive Type : Other, Electric Motor

Type : Automatic Lumps Granulator

Computerized : No

Material : Mild Steel

Lumps Granulators

Price 100000 INR / Piece

Minimum Order Quantity : 1 Piece

Drive Type : Other, Electric Motor

Type : Lumps Granulator

Computerized : No

Material : Mild Steel / Stainless Steel

Plastic Granulator

Price 100000 INR / Piece

Minimum Order Quantity : 1 Piece

Drive Type : Other, Electric

Type : Plastic Granulator

Computerized : No

Material : Mild Steel

Plastic Scrap Grinders

Price 40000 INR / Piece

Minimum Order Quantity : 1 Piece

Drive Type : Other, Belt Drive

Type : Plastic Scrap Grinder

Computerized : No

Material : Mild Steel

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry